Introduction

Ready-Mix concrete batching plants, precast concrete production and quarries need to treat or separate and reuse residual concrete from jobsites and concrete manufacturing processes in general to turn it into a valuable resource.

The CONSEP® Aggregate Reclaiming automated machineries enable different operations to fit all the user needs.

By choosing the advanced automation and remote-control options, the user can benefit of an "Industry 4.0 ready" solution.

CONSEP® follows the principles of environmental sustainability in accordance with the goals of the United Nations’ 2030 Agenda.

Automatic operation: user friendly (auto-on, auto-off + automatic cycle)

Modular design offers great flexibility in configuration according to specific on-site requirements

Significant reduction of unloading and parking times

Technical Specs

Description

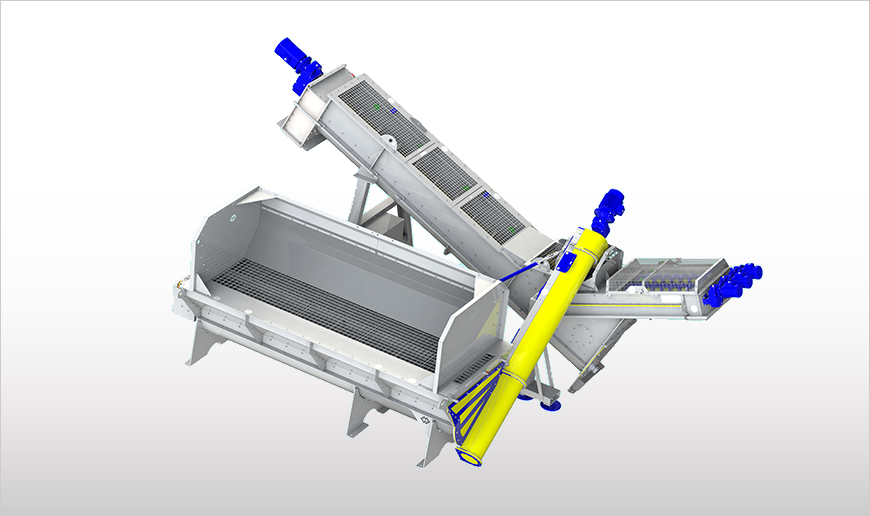

CONSEP CSC is a machinery for high production plants where a quick cleaning of truck mixers and concrete pumps (3-5 minutes on average) must be combined with a perfect washing out of the aggregates.

Moreover CONSEP CSC has the capability to separate and wash sand and gravels for allowing an easy recovery for new concrete production. CSC minimizes the needs to store and dispose of waste, it saves precious natural resources, and it ensures the compliance with the relevant laws.

Function

Diluted concrete is discharged into the Buffer where it is mixed with clear water.

The slurry is conveyed through a horizontal screw conveyor of the Buffer into a patented Inclined Screw Feeder entirely manufactured from SINT® engineering polymer, which transfers the slurry into the Classifier. The screen of the Classifier retains aggregates with a grain size larger than 5 mm. The aggregates are conveyed, washed with clear water, and finally discharged for reuse. The fine aggregates pass through the screen to Aggregate Reclaimer , which separates and washes the sand from the finest particles, allowing the immediate use of the recovered sand for new concrete production. In this way, the aggregates are conveyed, washed with purified water and separated into their main components for reuse.

Features

- Up to 2 receiving points (2 truck mixers at a time)

- Ready-Mix concrete plants: typically 10-12 truck mixers (washing only) or 3 truck mixers (washing out of residual concrete)

- Precast plants: 5 m3 per hour (washing out of residual concrete) - 12 m3 per hour (washing of equipment only)

- Dirty water discharge into tank with agitator: suspended solids 8 ~ 10%; 0 ~ 0.2 mm

- Recovery of washed pre-sorted aggregates (sand 1 ~ 5 mm / gravel 6 ~ 40 mm

Benefits

- Significant reduction of unloading and parking times

- Modular design offers great flexibility in configuration according to specific on-site requirements

- Automatic operation: user friendly (auto-on, auto-off + automatic cycle)

- Efficient and sustainable

- Time- and cost-saving wash-out of the equipment

- Savings in maintenance costs compared to simple sedimentation tanks

- Savings in raw material purchasing costs and waste disposal

- No costs for concrete demolition or for removal of concrete from the moulds