Technical Specs

Description

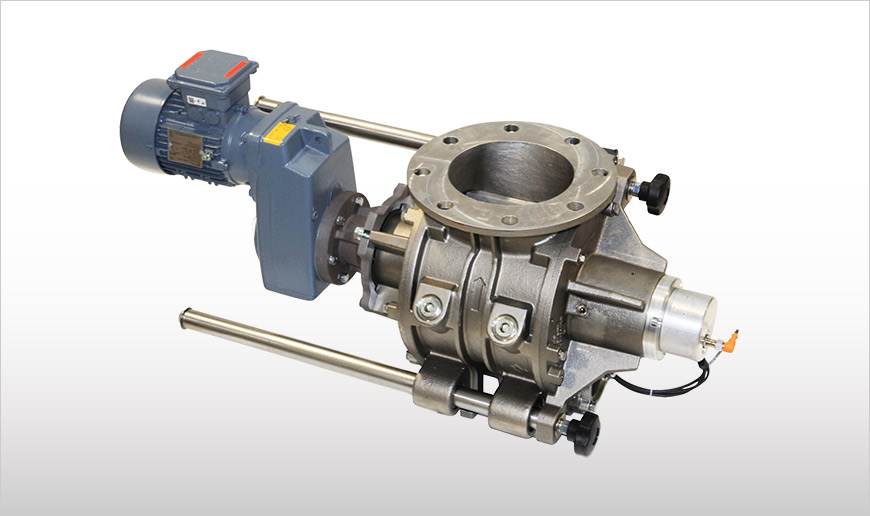

SlideOut Rotary Valves are engineered with a continuously revolving rotor featuring two compartments, both of which are filled with material simultaneously via the top inlet.

Function

The valves come in two distinct versions: REC and RES.

The REC Drop-through SlideOut Rotary Valve is equipped with a circular inlet and outlet. The material fed by the rotor falls by gravity through the lower outlet into a container or onto a downstream conveying system for further processing.

With the RES Blow-through SlideOut Rotary Valve also featuring a circular inlet flange and an outlet pipe connection on the bottom on both sides, after less than half a rotor revolution, the material is discharged and channelled into an air flow within a pneumatic conveying line.

Features

- Standard rotor with integrated shaft

- Drive unit mounted on rotor shaft

- Air-purged shaft seal

- Feed rate: 5-10-20-35 litres per revolution (0.17-0.35-0.70-1.2 cu ft/rev) for 2”, 3”, 4” and 5” conveying pipes

- Working temperature: -40 ~ 150 °C (-40 ~ 302 °F)

- Working pressure: up to 1 bar (14 psi)

- Casing: 316 SS

- EN 1092-1 PN 10 Flanges (DIN 2576)

- Sturdy and compact structure

- Various finishing options available

- EC 1935/2004-certified materials

- ATEX 20/22 certification

Benefits

- Simple, safe and cost-effective Maintenance

- Durable, long-lasting and space-efficient

- Flexible in handling of different types of materials

- Preserves physical properties of material handled