Newsletters

WAMGROUP News - Issue No. 3/2024

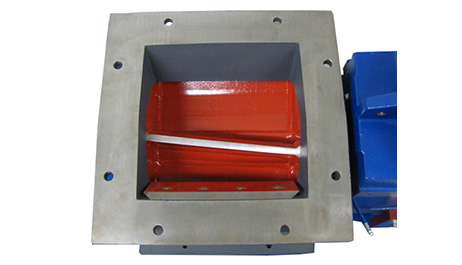

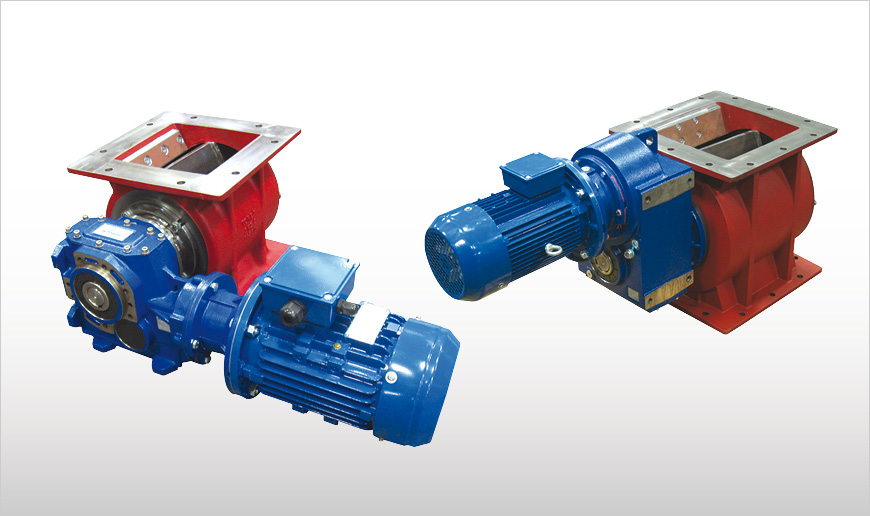

Heavy-duty design

Fill out the form to receive more information