Newsletters

WAMGROUP News - Issue No. 3/2024

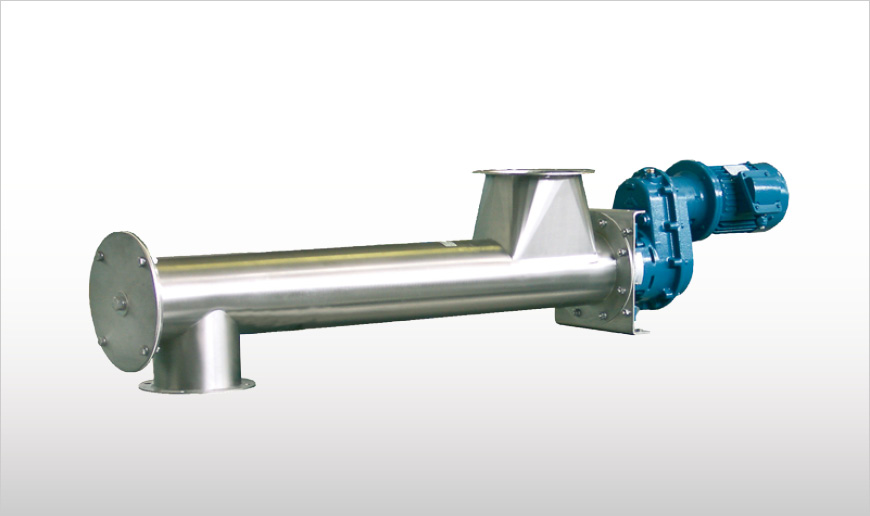

Ease of maintenance

Fill out the form to receive more information