Newsletters

WAMGROUP News - Issue No. 3/2024

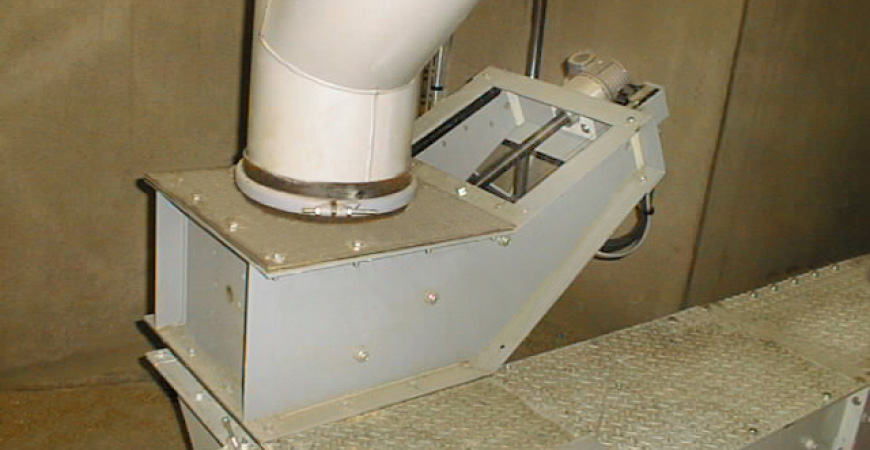

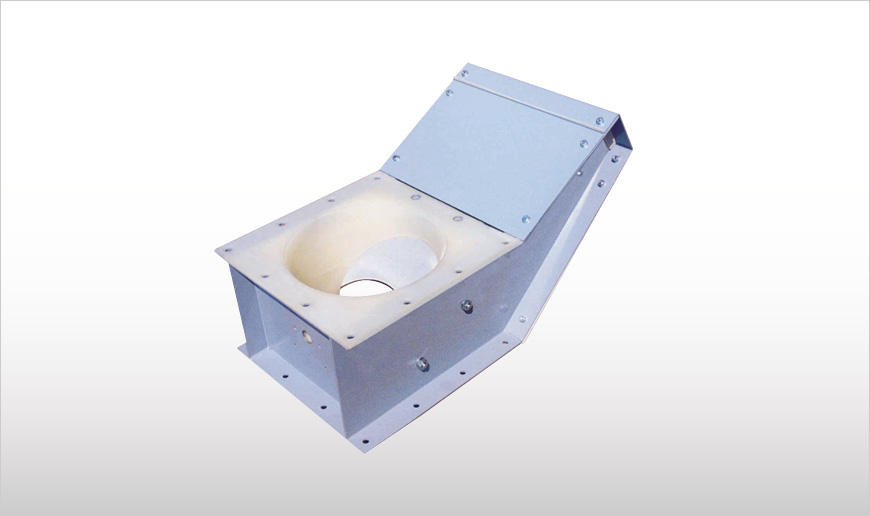

Flow interception and material flow control

Fill out the form to receive more information