Introduction

The increased use of WAM’s special SINT engineering polymer in designing the VL range makes these Slides Valves the ideal equipment for intercepting the flow of powdery or granular materials in gravity or conveying applications.

Reliable, versatile, durable with powdery or granular materials

Limited number of spare parts

Versions for virtually all industries available

Technical Specs

Description

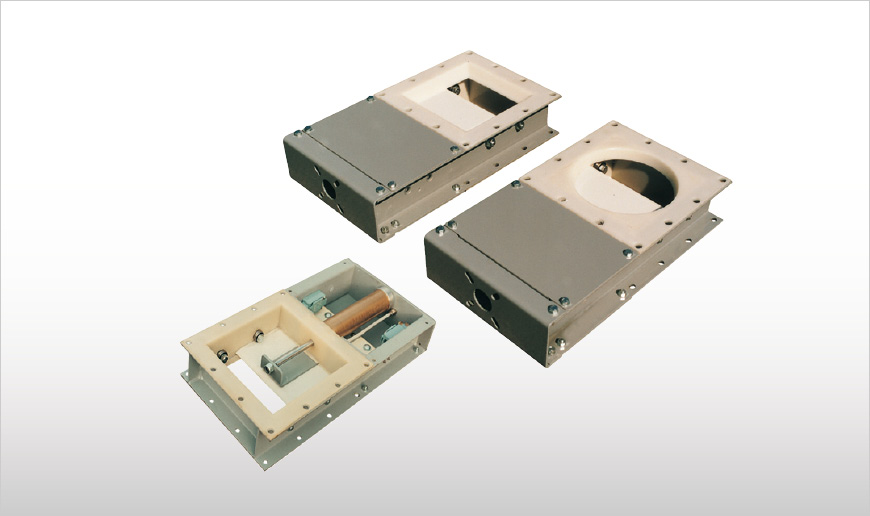

VL-type Slide Valves consist of a two-piece carbon or stainless steel frame partly coated with WAM’s SINT engineering polymer composite, as well as a sliding blade manufactured from SINT engineering polymer, carbon steel or stainless steel. The use of the unique SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. Moreover, it avoids the use of flange gaskets.

VL Slide Valves are available in a variety of configurations including rectangular sizes. In the VLQ version the valves come with a square, in the VLC version with a circular open cross section, whereas in the VLR-version it is rectangular. The VLS version with square cross section has a pneumatic actuator integrated in its frame.

Function

VL Slides Valves are used where flow of a powdery or granular material caused by gravity or conveying has to be intercepted. Slide valves may be fitted on a hopper or silo outlet, on inlets and outlets of mechanical conveyors, as well as on the inlet of telescopic loading spouts. For conveyor outlets in particular, the VLS version with integrated pneumatic actuator is a valid option due to its compact overall dimensions.

The special geometry of VL Slide Valves and the various options in blade design enable their application in virtually all industries including food processing.

Features

- Easy to handle

- Highly abrasion-resistant

- Easy and quick to fit

- Safe sealing with no additional measures due to the all-round dustproof seal lips integrated into the polymer coating

- Valve frames entirely coated with SINT engineering polymer composite (food-grade, FDA/EN-approved on request)

- Absence of pinch points and exposed moving parts ensures safe operation

- Horizontal or vertical mounting

- Efficient sealing against fine powders and dust

- Integrated service inlet to deflect material away from seals and rollers, thus reducing wear

- Interchangeable actuators: manual, pneumatic, electric gear motor

- PATENTED

Benefits

- Low-friction sliding blade fully SINT polymer-coated in standard version

- Depending on application, blades manufactured from various materials

- Limited number of parts make dismantling and reassembly of the valve easy

- VLS with pneumatic actuator integrated inside valve frame offering smallest possible overall dimensions

Options

- ATEX-certification

- Available in different materials

- Ex-stock delivery