Introduction

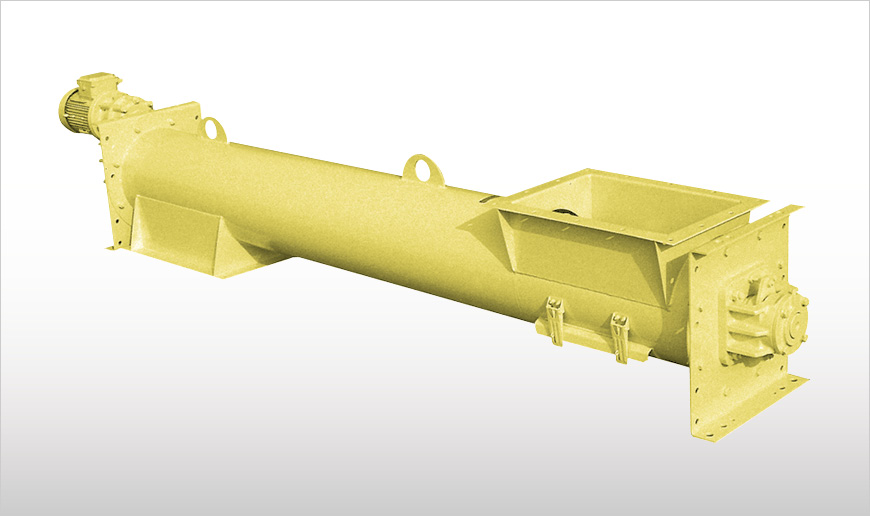

The modular CAO Tubular Trough Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. They are widely used all over the world in industries such as flour milling, animal feed milling. In general, CAO Tubular Screw Conveyors and Feeders are suitable for applications that require minimum material residue and maximum conservation of particle size of the material when handled.

Industrial quality product

Modular design features ensuring matching spare parts

Worldwide spare parts availability through WAM subsidiaries

Technical Specs

Description

The modular CAO Tubular Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. CAO Screw Conveyors are manufactured from carbon steel with suitable surface finishing. They consist of a tubular trough equipped with at least one inlet and outlet spout, an end plate at each tubular trough end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with adjustable shaft seal, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, CAO Tubular Screw Conveyors are equipped with a gear motor appropriate for the application.

Depending on the material to be handled, CAO Tubular Screw Conveyors come in a light or medium heavy-duty design.

Both versions are available with ATEX, Zone 22 certification.

Function

The light-duty version, CAO_L, is mainly used for feeding and conveying flour and flour milling by-products. The medium heavy-duty version, CAO_P, is mainly used in animal feed milling with products such as cereals, meals and milling by-products. In general, CAO Tubular Screw Conveyors and Feeders are suitable for applications that require minimum material residue and maximum conservation of particle size of the material when handled.

Features

- Standard length tubular sections

- Helicoid flighting welded on centre pipe

- Powder-coated

- Flanged end bearing assemblies protected against material infiltration by adjustable shaft seals

- Wide range of intermediate hanger bearings designed for specific applications (self-lubricating versions included)

- Circular, square or rectangular inlet and outlet spouts complete with drilled WAM standard flanges

- Robust cast iron body, flanged end bearing assemblies with external bearings and manually adjustable packed gland seals

- Maintenance-free (or non) intermediate cast or fabricated hanger bearings with self-lubricating and other type slide bushes

- Splined shaft couplings

- Drive unit mounted at inlet or outlet end:

- Bare shaft

- Direct compact gear motor drive

- Direct gear motor drive with semi-elastic coupling

- Offset gear motor drive with chain transmission

- Offset drive with belt transmission

For light-duty version:

- Robust tubular trough in modular flanged sections in carbon or stainless steel

- Light-duty helicoid flighting welded on centre pipe in carbon or stainless steel

For medium heavy-duty version:

- Medium heavy-duty carbon steel helicoid flighting welded on centre pipe

- Robust tubular carbon steel trough in modular flanged sections

Benefits

- Industrial quality product

- Modular design features ensuring matching spare parts

- Worldwide spare parts availability through WAM subsidiaries

Options

- Circular, square, or rectangular substitute/additional inlet/outlet spouts with or without connecting flange

- Trough feet

- Overflow hatches

- Screws (augers) in various configurations (ribbon flight, paddles, others)

- Special shaft seals (gas or air-purged, grease chamber, others)

- Different drive configurations

- Jacketed outside tube

- Drop bottom tube

- Slide valves

- Flush outlets

- For medium heavy-duty version

- Screws manufactured from special wear-resistant materials

BOTH TYPES AVAILABLE WITH ATEX, ZONE 22 CERTIFICATION.