Introduction

In terms of functionality and cost-effectiveness, the DUSTFIX Industrial Dust Conditioner is the optimal solution for evacuating, conditioning, and disposing of dust across various industries. Its advanced technical features, innovative design, and exceptionally short processing time ensure dust-free discharge onto open trucks or belt conveyors.

Quick return on investment

Technical Specs

Description

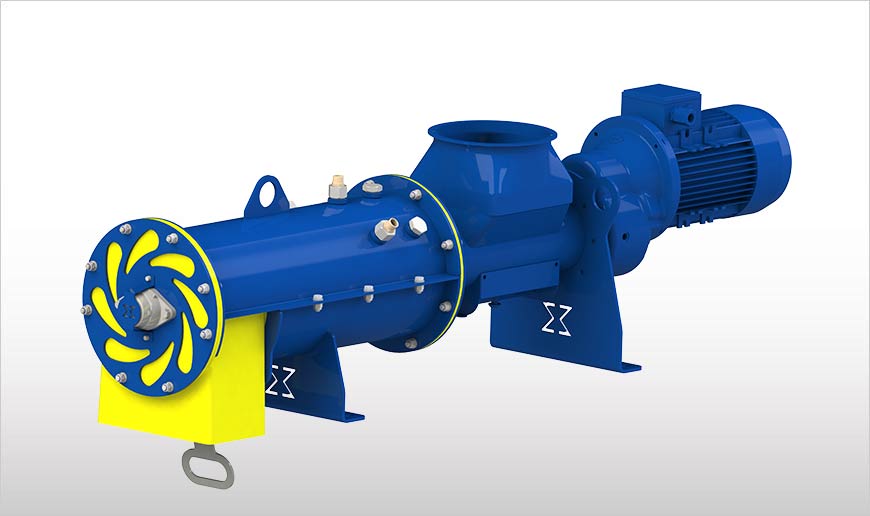

The DUSTFIX Industrial Dust Conditioner features a carbon-steel tubular housing with a SINT engineering polymer liner, a combined feeder screw and mixing shaft, a vertical inlet, a SINT flush outlet, liquid supply points in the conditioning section, and a drive unit with an integrated shaft seal.

Function

The DUSTFIX Industrial Dust Conditioner is the optimal solution for evacuating, conditioning, and disposing of industrial dusts, offering both functional efficiency and cost-effectiveness. Its advanced technical features, innovative use of SINT engineering polymers, and exceptionally short processing time make it ideal for continuous duty.

Features

- Capacity: 2 ~ 80 m3/h (1.2 ~ 47 cfm)

- Conditioning chamber manufactured from special non-stick anti-wear SINT engineering polymer

- Rotor shaft completely removable with modular, individually replaceable conditioning tools

- Dry feeding and conveying section

- Elastic SINT engineering polymer outlet safeguard

- Revolving inlet flange

Benefits

- Best and most cost-effective solution on the market

- Immediate reduction in dust disposal costs

- Simple and quick maintenance

- SINT engineering polymers by WAM for minimal maintenance, easy cleaning, and effective wear protection

- No material residue

- Low energy consumption

Options

- Control panel

- Equipment for liquid injection