Introduction

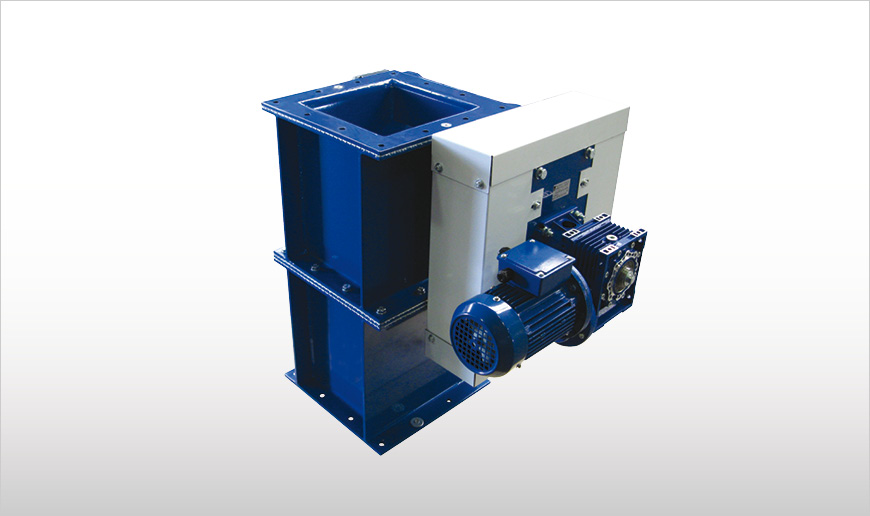

VDC Double Dump Valves are the ideal solution for controlled discharging of large particle size or particularly high temperature materials from silos, bins or hoppers in heavy-duty applications in virtually all industries.

Easy access for maintenance

Highly efficient with high temperature or abrasive materials with large particle size

Technical Specs

Description

VDC Double Dump Valves consist of a robust casing and two alternately activated flaps, one installed on top of the other.

VDC Double Dump Valves are the ideal solution for controlled discharging of particularly high temperature or abrasive, large particle size materials. They are most suitable for discharging dust from large de-dusting units and for heavy-duty applications in general, in virtually all industries. They are also used for processes that do not require continuous material flow.

Function

VDC Double Dump Valves are designed to withstand high temperatures, for abrasive materials and those with irregular particle size in bulk solids handling processes in which constant material flow is important.

Features

- Square inlets: from 200 x 200 mm to 500 x 500 mm (8 x 8” ~ 20 x 20”)

- Capacity: 1.2 m3/h ~ 17.7 m3/h (42.4 cfh ~ 625 cfh)

- Calculated for 600 activation cycles per hour at 50% loading

- Ambient temperature: -10 ~ 50 °C (14 ~ 120 °F)

- Working temperature: -10 ~ 500 °C (14 ~ 930 °F)

- Various materials available according to product handled

- Different types of control systems

Benefits

- Easy access for maintenance

- Smooth contact surfaces facilitate cleaning

- High efficiency even with high temperatures

- Excellent feeding properties

Options

Contact parts manufactured in wear-resistant materials on request.